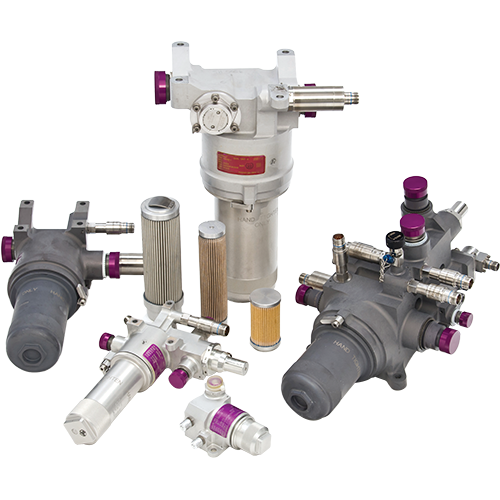

PTI’s custom designed filter manifolds integrate independent fluid system into one compact and efficient manifold providing greater reliability and improved maintainability while optimizing weight and mission performance. International customers have selected PTI as their source for filtration and fluid control products.

PTI Technologies engineers reliable, high-performance and fully integrated filtration solutions for aircraft fluid systems. PTI’s complex filtration and fluid control manifolds ensure maximum protection and efficiency against contaminants in systems with operating pressures up to 5,000 PSI. Technical innovation enhanced by our customer focus has made PTI a trusted partner in the aerospace market.

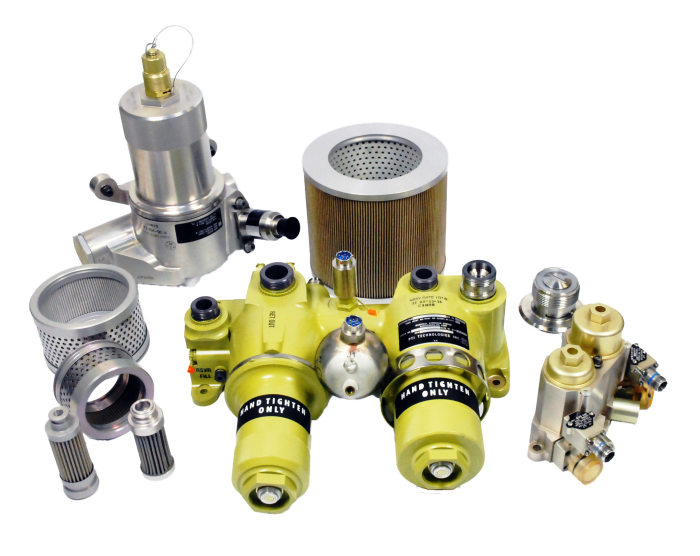

PTI has a extensive pedigree in commercial and military aviation, but we also produce products for business jets and regional aircraft. The hydraulic filter modules for the Falcon 7X are examples of complex multi-component modules and incorporate the following components:

- Pressure, case drain and return filter elements

- Relief, bypass and check valves

- Pressure switches, pressure transducers

- Electrical / visual delta-P indicators

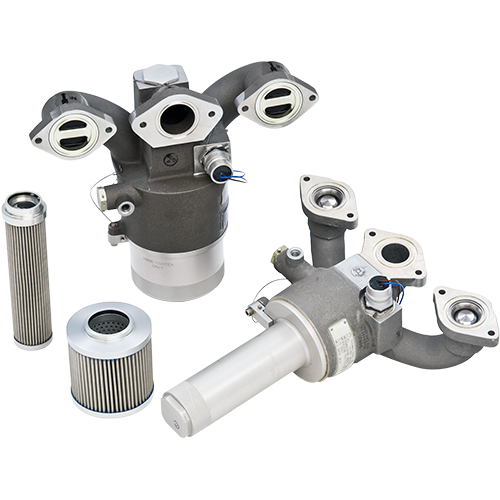

In addition to multi-component modules, PTI also designs and manufacturers filter sub-assemblies for direct integration into engine, gearbox or pump housings. The engine lube filter sub-assembly for the JSF F-135 engine consists of a filter bowl, filter element and a combination valve assembly with by-pass, shut-off and reverse flow functions.

PTI Technologies designs and produces many of the hydraulic filtration components on Boeing’s family of aircraft. Our product content ranges from individual filter elements to complete integrated hydraulic system modules like the Boeing 767 Engine Driven Pump / Air Driven Pump Module.

PTI Technologies designs and produces many of the Hydraulic Filtration Applications on Boeing’s family of Aircraft. The Boeing 787 liquid cooling system provides cooling flow to the Primary Electronics Cooling System (PECS), the Integrated Cooling System (ICS) and the Forward Cargo Air Conditioning System (FCAC) – which PTI provides the filtration package modules for all three systems.

PTI has developed a number of innovative filter designs and aviation firsts. The RR 250 Combined Engine Fuel Assembly filter module is a unique design which incorporates engine lube and fuel filters in the same module. This design provides significant weight savings and a smaller space claim as well as the added benefit of cooling the lube oil via thermal transfer with the relatively cool fuel.

PTI’s multi-component modules combine a number of functions into a compact package. The EJ 200 engine lube oil filter module for the Eurofighter incorporates both pressure and return lube oil filtration as well as bypass valves and electrical / visual indicators.

PTI’s custom-designed Radar Coolant Filter Module provides Liquid Cooling Filtration in support of the radar fluid systems integrated into one compact and efficient manifold providing greater reliability and improved maintainability.

Key Features:

- Face Seal Design

- Filters Polyalphaolefin (PAO)

- 180 psi Operating Pressure

- Differential Pressure Indicator

- System Relief Valve

- Shut-off Valve

- Bypass Valve

PTI’s filter modules support military aircraft systems to handle vital functions – such as hydraulic actuation, fuel distribution, lubrication systems, environmental control, avionics and electronics all of which depend on fluid cleanliness to perform safely and reliably during mission-critical operations.

PTI’s filter modules are available on a wide range of military platforms such as:

- F-35

- F-15

- F-16

- F/A-18

- B-2

- U-2

- KC-46

- Eurofighter

Platform

GE T700/CT7

UH-60 Black Hawk

AH-64 Apache

Function

Performs dual functions on gas turbine engines:

• Provides hot air flow for engine anti-ice protection

• Automatically bleeds air from the engine during the starting cycle

Platform

CH-148 Cyclone

SH-60/MH-60 Seahawk

HH-60W (CRH)

Function

Jettison fuel from fuel tank

Platform

CH-148 Cyclone

Function

Vents fuel tanks and prevents over pressurization

Platform

F-14 Tomcat

Function

Controls fuel flow; used as a wing tank shut off

Platform

KC-10 Extender

Function

In-flight aerial refueling/fuel transfer

Platform

V-22 Osprey

Function

Provides a single aircraft fuel line connection to refuel and defuel through dual valve sections

Platform

Boeing F-15 Eagle

Function

Used to engage a flying boom from a tanker aircraft for aerial refueling

Platform

KAI KF-21 Boramae

Function

Used to engage a flying boom from a tanker aircraft for aerial refueling

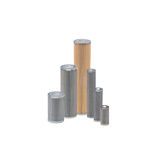

PTI Technologies designs and produces a wide range of hydraulic filter elements used in today’s commercial and military aircraft and ground support systems. Filter elements comprised of depth-type filtration media combine high efficiency particle removal while optimizing contamination capacity. Operating environments include pressures up to 5,000 psid and temperatures ranging from -65°F to 350°F.

PTI provides filtration solutions for engine applications ranging from the PT6 to the PW4000 series engines. Applications include fuel, lubrication and pneumatic systems. Filter elements of the constructed of depth-type filtration media or woven wire mesh are offered in both disposable and cleanable configurations.

In addition to pleated filter elements, PTI provides screen, strainer and metal edge type filter elements for use in last chance, fuel wash flow, scavenge lube oil and other systems requiring protection for downstream components.

Drawing on our longstanding experience in the design, and production of metal fiber media filter elements, PTI has led development of improved hydraulic system filter elements for the US Army. Early tests have shown a significant improvement in system cleanliness, on stream life and resistance to cyclic flow contaminant migration.

PTI Technologies’ random fiber filter media is the highest performance media on the market today. PTI’s 421® Metal Fiber Media element design extends the life of components and reduces annual maintenance cost, thereby providing a higher level of operational reliability and improved safety.

Platform

- AH-64 Apache

P/N 7595726-101 - H-60 Black Hawk

P/N 7596335-101 - Aviation Ground Power Unit (AGPU)

P/N 7600570-101

- Service Interval: C-check

Boeing Series

- 737-700

- 737-800

- 737-600

- 37-900

- 747-400

- 757-200

- 757-300

- 767-200

- 767-300

- 767-300F

- 767-400ER

- 777-200

- 777-300

- 777-300ER

- 777-200LR

- 777F Series

Designed to remove airborne particles including dust, pollen, lint, smoke, spores, hydraulic mist, bacteria, viruses and other contaminants

- 99.97% efficient in removing 0.3 micron particles

- Meets requirements of a 1200 CFM system

- Service Interval: C-check

- Protects from airborne bacteria and viruses

Boeing Series

- 737-300

- 737-400

- 737-500

- 737-600

- 737-700

- 737-800

- 737-900

- 757-200

- 757-300

Designed to remove contaminants from the avionics equipment cooling air supply

- Service Interval: C-check

- 100% efficiency at 15 micron particle size

Boeing Series

- 737-600

- 737-700

- 737-800

- 737-900

- 757-200

- 757-300

Designed to remove contaminants from the electronics equipment cooling air supply

- Service Interval: 2A-Check

Boeing Series

- 717-200

- MD-90-30

- 99.97% efficient in removing 0.3 micron particles

- Skydrol® Tested

- Protects from airborne bacteria and viruses

Embraer Series

- 170-100 STD

- 170-100 LR

- 170-100 SU

- 170-100 SE

- 170-200 STD

- 170-200 LR

- 170-200 SU

- 190-100 STD

- 190-100 LR

- 190-100 IGW

- 190-100 ECJ

- 190-200 STD

- 190-200 LR

- 190-200 IGW

Designed to remove contaminants from the avionics equipment cooling air supply

- 99% efficient for particles 50 micron and greater in an airstream at 1500 SCFM

- Service Interval: C-check

Boeing Series

- 777-200

- 777-200LR

- 777-300

- 777-300ER

- 777F

Designed to remove airborne particles including dust, pollen, lint, smoke, spores, hydraulic mist, bacteria, viruses and other contaminants

- 99.97% efficient in removing 0.3 micron particles

- Rated Airflow: 1500 SCFM

- Service Interval: C-check

- Protects from airborne bacteria and viruses

- Skydrol® tested

Boeing Series

- 767-300

Designed to remove airborne particles including dust, pollen, lint, smoke, spores, hydraulic mist, bacteria, viruses and other contaminants

- 99.9% efficient in removing 0.3 micron particles

- Rated Airflow: 680 SCFM

- Service Interval: C-check

- Skydrol® Tested

Boeing Series

- 747-400

- 747-400D

- 747-400F

Designed to enhance taste and eliminate odor

- Disposable

- 5 Micron

- Flow Rate: 1 gpm

(3.8 lpm) - Capacity: 3000 gallons

(11 356,2 liters) - Certified to NSF Standards

Airbus Series

- A318

- A319

- A320

- A321

- A330

- A340

Boeing Series

- 737

- 777

- CRJ 700

- CRJ 900

Designed to enhance taste and eliminate odor

- Disposable

- 5 Micron

- Flow Rate: 1.3 gpm

(4.9 lpm) - Capacity: 5000 gallons

(18 927,06 liters) - Certified to NSF Standards

Airbus Series

- A318

- A319

- A320

- A330

- A340

Boeing Series

- 747

- DC-9

- DC-10

- KC-10

- MD-81

- MD-82

- MD-83

- MD-87

Designed to enhance taste and eliminate odor, and protect against pathogens, parasitic cysts, disease, bacteria and viruses

- Disposable

- 0.4 Micron

- Flow Rate: 1 gpm

(3.8 lpm) - Capacity: 1000 gallons

(3785.4 liters) - Certified to NSF Standards

Airbus Series

- A318

- A319

- A320

- A321

- A330

- A340

Boeing Series

- 717-200

Designed to enhance taste and eliminate odor

- Disposable

- 50 Micron

- Flow Rate: 1 gpm

(3.8 lpm) - Capacity: 3000 gallons

(11356.2 liters) - Certified to NSF Standards

Airbus Series:

- A318

- A319

- A320

- A321

- A330

- A340

Boeing Series:

- 737

- 747

- 757

- 767

- 777

This rolling diaphragm indicator detects differential pressures as low as 5 psid +/- 0.5 psid up to 15 psid +/- 1.5 psid while maintaining a size compact enough to be mounted in a SAE-AS33514-8 port. High pressure sensing port is located radially on the OD just below the .750-16 UNJF mounting threads with the low pressure sensing port opposite and along the axis of the signal button. Signal: Visual. Reset: Manual.

Electrical and visual design couples MIL-S-8805 microswitch to the magnetic pop-out button. The mechanical motion of the pop-out button drives the snap acting SPDT microswitch. The switch can be wired for normally open or normally closed circuits. Hermetically sealed, gold contact switches recommended for all high temperature (to 500ºF) or low load applications (6 Volt, 0.010 amp circuit). Many mounting configurations and electrical connectors are available, or can be built to customer specification. Signal: Electrical and Visual. Reset: Manual (Automatic reset also available).

This indicator has a high pressure sensing port located at the bottom of the indicator, opposite and along the axis of the signal button. The low pressure sensing port is located radially. Signal: Visual. Reset: Manual.

Compact design provides a visual pop-out button signaling impending bypass. With the application of additional pressure, the indicator cracks to permit bypass. The standard unit designed for use with a 0-12 GPM flow rate, 50 psid +/- 5 psid actuation, 60 psid +/- 10 psid cracks with a 10 psid minimum between actuation and crack. High pressure sensing port is located at the bottom of the indicator, opposite and along the axis of the signal button. The low pressure sensing port and bypass openings are located. Signal and bypass functions are accomplished in a very small, lightweight package. The overall length of the indicator with bypass is 1.800″ with a 0.743″ OD. Signal: Visual. Reset: Manual.

Used to produce heat or pressure to ignite such items as safety fuses, propellants, powders, and thermal battery systems. NEco has designed, manufactured and tested a wide variety of controlled output igniters for aerospace, commercial and defense applications. NEco’s igniters are offered in low to high current ranges and in various all-fire and no-fire configurations; single or dual bridgewire designs are also available. All NEco igniters are designed and manufactured to provide optimum performance and reliability. NEco offers MIL DTL 23659E qualified igniters in both a single and dual bridgewire configuration.

NEco has designed, manufactured and tested a wide variety of controlled output igniters for military, aerospace and commercial applications. NEco igniters are offered in low to high current ranges and in various all-fire and no-fire configuration; single or dual bridgewire designs are also available. All igniters are designed and manufactured to provide optimum performance and reliability.

Gas and pressure cartridges are designed to generate a precisely controlled volume of gas output and provide energy for the activation of mechanical devices. The Ordnance Technology Division of NEco designs and manufactures a complete line of pyrotechnic gas generator and pressure cartridges to exacting customer and military specifications. With over four decades of experience, NEco is an established leader in the technological advancement of reliable pyrotechnic gas generators and pressure cartridges.

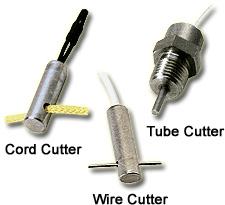

Pyrotechnic cord cutters are designed to cut lanyards, cables, and cords. A popular version of this device simultaneously severs a Kevlar® Cable (rated at 750 lbs.) and two 24 AWG wires within 10 milliseconds of initiation.

Pyrotechnic cable cutters and wire cutters are designed to cut both solid and multiple stranded wire within 20 milliseconds of initiation. One variant of this device severs a solid 0.033” diameter stainless steel spring wire in less than 20 milliseconds.

Tube cutters are designed to open pressure diaphragms or to completely sever metal tubes of varying diameters and wall thicknesses, including those carrying pressurized fluids. The cutters are available with RFI protection in accordance with MIL-M-23700.

Give us a call today for all your pyro cutter needs including pyrotechnic cable cutters, cord cutters and pyrotechnic igniter cutters.

Developed and designed to generate a precisely controlled volume of gas output to provide activation energy for mechanical devices. NEco designs and manufactures a complete line of pyrotechnic gas generators and pressure cartridges to exacting customer and military specifications. NEco also manufacturers gas generators that require a time delay (Electronic Time Delays) before the activation energy is utilized when needed.

Piston Actuators are linear motion devices designed to perform mechanical work. They are available in various sizes, force outputs, and stroke capabilities. NEco’s miniature piston actuator line includes devices that can provide forces in excess of 250 lbs. with stroke lengths up to 0.270 inch.

These devices are available in various all-fire and no-fire configurations, including several that are qualified to the 1-Amp, 1-Watt requirements of MIL-STD-1512. Many are used in military and aerospace applications that demand the highest level of reliability. All devices are hermetically sealed and are offered in both standard and special configurations.

Retracting Actuators, also known as pin pullers, also produce a linear motion, but upon activitation, the piston retracts into the housing instantaneously. These devices are extremely light and compact requiring only a few volts to initiate and can complete their stroke within milliseconds.

Retracting Actuators can be used to prevent the linear or rotational motion of more massive objects but when activated, will allow the required motion. All of the devices are hermetically sealed and are offered in both standard and special configurations.

NEco designs and manufacturers various Thermal Relays and Fuses in the configuration required by our customer. Known as a ‘one shot SPST’, NEco’s Thermal Relays and Fuses are hermetically sealed devices available in either the open or closed configuration. Our products operate over a wide temperature range with firing times as low as 2 milliseconds and switch rating from 1.5 to 25 amps. NEco’s Thermal Relays perform at a reliability rate of 99.9995%. The clear glass case allows visibility to determine the state of the switch/fuse.

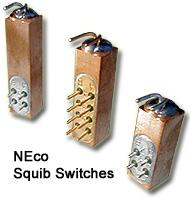

Developed with a unique locking feature that assures positive retention of the switched position. This ‘one-shot’ reliability is imperative in missiles, weapons, and aerospace applications where extreme conditions of shock, load, and vibration exist.

NEco’s squib switches are available in 2, 4, 6 and 8 pole configurations, with various make and break combinations. Each pole is rated for 10 amps continuous current and capable of much higher currents in pulsed applications.

Actuated by squibs of various sensitivities with ultra-fast or time-delayed characteristics, NEco switches out-perform large, environment-sensitive relays in critical areas such as weight saving, simultaneous switching of multi-high current circuits, and accuracy and stability under extreme environmental conditions.

Features

- 350 psi (24 bar) operating pressure

- Element collapse ratings of 150 psid (10 bar)

- 50 & 70 gpm (189 & 265 lpm) nominal flow rates

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- Optional DryPak™ moisture control media

- SAE straight thread or NPT ports

- Visual indicator standard

Duplex Filter Assemblies

Medium Pressure Hydraulic Filter Assemblies

Features

- 2,400 psi (166 bar) operating pressure

- 40, 80 & 100 gpm (151, 303 & 379 lpm) nominal flow rates

- SAE -24 straight thread or SAE 4-bolt flange ports

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- Optional visual & electrical indicators

- Self locking transfer valve

- Automatic bleed-over valve

Duplex Filter Assemblies

Low Pressure Hydraulic Filter Assemblies

Features

- 350 psi (24 bar) operating pressure

- 40, 80 & 100 gpm (151, 303 & 379 lpm) nominal flow rates

- SAE -24 straight thread or SAE 4-bolt flange ports

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- Optional visual & electrical indicators

- Self locking transfer valve

- Automatic bleed-over valve

Duplex Filter Assemblies

Features

- 350 psi (24 bar) operating pressure

- 60 & 100 gpm (227 & 379 lpm) nominal flow rates

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- SAE Code 61 4-bolt flange ports

- Visual indicator

- Transfer valve and convenient bleed valve provides for smooth changeover

Suction Filter Assemblies

For Hydraulic and Lube Oil Applications

Features

- Element collapse rating 75 psid (5 bar)

- 50 gpm (189 lpm) nominal flow rate

- 3 psid bypass valve built into element

- Replaces CanFlo P/N CF 10-E

Features

- 350 psi (24 bar) operating pressure

- Element collapse rating of 75 psid (5 bar)

- 525 psi (36 bar) static burst pressure

- 30 & 40 gpm (114 & 151 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- NPT or SAE straight thread ports

- Optional visual indicator

- Interchangeable with Pall 7400/9540 elements

Spin-On Filter Assemblies

For Hydraulic and Lube Oil Applications

Features

- 200 psi (14 bar) operating pressure

- Element collapse rating of 75 psid (5 bar)

- Static burst pressure 300 psi (21 bar)

- 50 & 70 gpm (189 & 265 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional cellulose media

- NPT or SAE straight thread ports

- Optional visual indicator

- Interchangeable with competitive spin-ons

Spin-On Filter Assemblies

For Hydraulic and Lube Oil Applications

Features

- Operating pressure 200 psi (14 bar)

- Element collapse rating of 75 psid (5 bar)

- Static burst pressure 400 psi (28 bar)

- 30 & 40 gpm (114 & 151 lpm) nominal flow rates

- Elements available with cellulose media

- NPT or SAE straight thread ports

- Optional visual indicator

- Interchangeable with competitive spin-ons

For Hydraulic Applications

Features

- 200 psi (14 bar) operating pressure

- Element collapse rating of 75 psid (5 bar)

- 25, 70, 100 & 160 gpm (95, 265, 379 & 606 lpm) nominal flow rates

- SAE Straight thread ports or SAE flanges available

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media®

- Optional DryPak™ moisture control media

- Standard 50 psid (3.4 bar) bypass valve

For Hydraulic Applications

Features

- 150 psi (10 bar) operating pressure

- Element collapse rating of 75 psid (5 bar) & 150 psid (10 bar)

- 70, 100 & 150 gpm (265, 379 & 568 lpm) nominal flow rates

- NPT or SAE straight thread ports

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media®

- Optional visual & electrical indicators

- 3 & 25 psid bypass options available

High Pressure Hydraulic Filter Assemblies

Features

- 6,000 psi (414 bar) operating pressure

- Element collapse ratings of 300 & 3000 psid (21 & 207 bar)

- 15, 25 & 30 gpm (57, 95 & 114 lpm) nominal flow rates

- SAE -12 or SAE -16 ports

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- Optional thermal lockout

- Valve options include – bypass, reverse flow & no bypass

Features

- 400 psi (28 bar) operating pressure

- 15 gpm (57 lpm) nominal flow rate

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- 3/4″ NPT ports

- Optional 50 psid (3.4 bar) ±10% bypass valve

Inline Type Hydraulic Filter Assemblies

Low Pressure Hydraulic Filter Assemblies

Features

- 150 psi (10 bar) operating pressure

- 120 gpm (454 lpm) nominal flow rate

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- Optional DryPak™ moisture control media

- RePak® (Replaceable Pleat Pack) element

- NPT or ANSI flange ports

- Optional visual & electrical indicators

Inline Type Hydraulic Filter Assemblies

Low Pressure Hydraulic Filter Assemblies

Features

- 400 psi (28 bar) operating pressure

- 150 & 250 gpm (568 & 946 lpm) nominal flow rates

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- SAE 4-Bolt flange ports

- Optional visual & electrical indicators

Filter Assemblies

Low Pressure Hydraulic Filter Assemblies

Features

- 350 psi (24 bar) operating pressure

- 18, 35 & 50 gpm (68, 132 & 189 lpm) nominal flow rates

- SAE -20 straight thread ports

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- Optional visual & electrical indicators

L-Type Hydraulic Filters

Low Pressure Hydraulic & Lubrication System Return Line Filter Assemblies

Features

- 150 psi (10 bar) operating pressure

- 40 and 80 gpm (151 & 303 lpm) nominal flow rates

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- 1¼” NPT Ports

L-Type Hydraulic Filter Assemblies

Hydraulic & Lubrication System Return-Line Filter Assemblies

Features

- 150 psi (10 bar) operating pressure

- 40 and 80 gpm (151 & 303 lpm) nominal flow rates

- Elements available with ßx(c) ≥ 1,000 Glas-Tech® media

- 1¼” NPT ports

- FHD series assembly designed for military style AN6236-3 elements

Medium Pressure Hydraulic Filter Assemblies

Features

- 2,000 psi (138 bar) operating pressure

- 25 gpm (95 lpm) nominal flow rate

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- SAE -16 straight thread ports

- Optional visual & visual/electrical indicators

- Utilize PTI F1L series elements

High Pressure Hydraulic Filter Assemblies

Features

- 6,000 psi (414 bar) operating pressure

- Element collapse ratings of 300 & 3000 psid (21 & 307 bar)

- 50, 80 & 120 gpm (189, 303 & 454 lpm) nominal flow rates

- SAE ports or SAE flanges

- Elements available with ßx(c) ≥ 1000 Glas-Tech® media

- Optional thermal lockout

- Valve options include – bypass, reverse flow & no bypass

Features

- Fit PTI F1F, F1M, F2P, F1P, F7F & F7L filter assemblies

- Element collapse rating 300 psi (21 bar) or 3000 psi (207 bar)

- 15, 25 & 30 gpm (57, 95 & 114 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

Technical and ordering information, AN-6236 Style Filter Elements, 75 & 300 psid collapse

Technical and ordering information, AN-6235 Style Filter Elements, 150, 200, 300, 3000 & 4500 psid collapse

421® Soft Sintered Element

PTI Technologies metal filter elements begin with our proprietary 421-brand random fiber depth media. PTI’s 421® media is made from very small fibers, which are annealed and compressed to exacting specifications. The media is available in 316L stainless steel, and also other specialty alloys, such as Hastelloy R.

Because we make 421® ourselves, we don’t have to rely on “off-the-shelf” media to solve our customer’s problems. Instead, we are able to match our customer’s needs to very specific filtration solutions. Many times, we will create a custom media for a given customer application.

Double Layer Media with High Dirt Holding Capacity

Features

- PTI developed proprietary filter element media

- Multi-layer construction

- Double layer gradient media:

- Improved efficiency – ßx(c)≥1000

- Lower clean differential pressures

- Higher dirt holding capacity

- Enhanced chemical compatibility

- Offers a broader variety of applications

- Includes water/glycol, phosphate esters, etc.

- Optional DryPak™ moisture control media

- Increased shelf life

Standard Micron Rated Particle Elements with Integral Water Removal

Features

- Long-Life PTI ßx(c) ≥ 1000 Glas-Tech® media

- Low cost ongoing moisture control

- No significant clean delta-p increase

- Minor delta-p increase with a water saturated element

- Extends element life

- Controls and reduces free water, emulsified water, and dissolved water while maintaining the ISO cleanliness of the system

High Collapse Replaceable Media Pack Elements

Features

- Collapse rating 200 psid (14 bar)

- Reusable center tube assembly

- 150 & 250 gpm (568 & 946 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

Interchange Elements

Features

- Element collapse rating 150 psid (10 bar)

- 150 & 250 gpm (568 & 946 lpm) nominal flow rates

- Elements available with Glas-Tech III ßx(c) ≥ 1000 proprietary media

- Optional DryPak™ moisture control media

- Easy lift handles

- Replacement for Pall 8304 & 8314 series filter elements

Replaceable Pleat Pack Filter Elements

Features

- Fit PTI F7G & F8G filter assemblies

- Upgrades PTI P83 and DP83 elements

- Reusable center tube assembly

- Element collapse rating 150 psid (10 bar)

- 150 & 250 gpm (568 & 946 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ Moisture control media

Features

- Fit PTI F1F, F1M, F2P, F1P, F7F & F7L filter assemblies

- Element collapse rating 300 psi (21 bar) or 3000 psi (207 bar)

- 50, 80 & 120 gpm (189, 303 & 454 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

Features

- Fits PTI F7G & F8G filter assemblies

- Element collapse rating 150 psid (10 bar)

- 100, 150 & 250 gpm (379, 568 & 946 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

Element Interchange Series for Pall 9600 & 9601

Features

- Replaces Pall Series 9600 & 9601 filter elements

- Element collapse rating 150 psid (10 bar) or 3000 psid (207 bar)

- 15, 30, 50 & 60 gpm (57, 114, 189 & 227 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

High and Low Pressure Filter Elements

Features

- Element Collapse Rating 200 psi (14 bar) or 3000 psi (207 bar)

- 10 & 20 gpm (38 & 76 lpm) Nominal Flow Rates

- Elements Available with ßx(c) ≥ 1000 Glas-Tech® Media

- Optional DryPak™ Moisture Control Media

- Replacement Element For Pall 9020 and 9021 Filter Assemblies

Advanced Interchanges For Hilco/Kaydon Elements

Features

- Replaces Hilco, Kaydon, Refilco and other 6×18 & 6×36 size filter elements

- Element collapse rating 100 psid (7 bar)

- 100, 150, 200 & 250 gpm (379, 568, 757 & 946 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

Low Pressure Filters for Suction Applications

Features

- Element collapse rating 75 psid (5 bar)

- 50 gpm (189 lpm) nominal flow rate

- 3 psid Bypass valve built into element

- Replaces CanFlo P/N CF 10-E

Medium Pressure Hydraulic Filter Assemblies

Features

- 350 psi (24 bar) operating pressure

- Element collapse rating of 75 psid (5 bar)

- 525 psi (36 bar) static burst pressure

- 30 & 40 gpm (114 & 151 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Interchangeable with Pall 7400/9540 elements

For Hydraulic and Lube Oil Applications

Features

- 200 psi (14 bar) operating pressure

- Element collapse rating of 75 psid (5 bar)

- Static burst pressure 300 psi (21 bar)

- 50 & 70 gpm (189 & 265 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional cellulose media

- NPT or SAE straight thread ports

- Optional visual indicator

- Interchangeable with competitive spin-ons

For Hydraulic and Lube Oil Applications

Features

- Operating pressure 200 psi (14 bar)

- Element collapse rating of 75 psid (5 bar)

- Static burst pressure 400 psi (28 bar)

- 30 & 40 gpm (114 & 151 lpm) nominal flow rates

- Elements available with cellulose media

- NPT or SAE straight thread ports

- Optional visual indicator

- Interchangeable with competitive spin-ons

Features

- Fit PTI F7G & F8G filter assemblies

- Element collapse rating 150 psid (10 bar)

- 150 & 250 gpm (568 & 946 lpm) nominal flow rates

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

For Hydraulic and Lube Oil Applications

Features

- Fits PTI RePak™ 50/70 (FSF) series filter assemblies

- Reusable steel center tube assembly

- Element collapse rating 150 psid (10 bar)

- 50 & 70 gpm (189 & 265 lpm) nominal flow rate

- Elements available with Glas-Tech® ßx(c) ≥ 1000 media

- Optional DryPak™ moisture control media

PTI provides high performance filtration products for high, medium and low pressure hydraulic applications as well as lubrication systems with inline, duplex, intank, inverse-T and spin-on filter assemblies.