421® Metal Fiber Media Filter

UPDATE

January 19, 2020

PTI Partners with the U.S. Army to Reduce Failures

421® Metal Fiber Media Filter Background

Particulate contamination is one of the main sources of failure in a helicopter hydraulic system that can result in high risks, both to human life and equipment cost if a failure occurs during mission-critical operations. Helicopter applications require that the critical hydraulic system components reliably operate under extreme operating pressures, temperatures, vibration/shock, and cyclic flow flight conditions. Fortunately, induced failures can be significantly reduced or eliminated if appropriate contamination control is implemented during design and development phases.

The U.S. Army has been using micro-fiberglass media filter element designs for both the Apache AH-64 and Black Hawk UH-60 fleet of helicopters since their introduction into service. For over a decade the U.S. Army has not been satisfied with the fluid cleanliness of the hydraulic systems in these aircraft. Knowing the extreme flight operating conditions these aircraft endure and the impact this has on hydraulic system failures, PTI Technologies was sourced by the U.S. Army to develop and implement a robust contamination control filter element design to achieve desired fluid cleanliness improvements.

Through rigorous testing, PTI’s metal fiber media filter element design outperformed the original qualified micro-fiberglass media filter element design. PTI’s metal fiber media filter element design not only improves the performance of the hydraulic system significantly, but also extends the life of components and reduces annual maintenance cost, thereby providing a higher level of operational reliability and improved safety.

H-60, AH-64, AGPU: New Hydraulic Filters Reduce Failures

This article initially appeared in PS 786 (May 18), pp. 38-39, and in PS FB post (Dec 17).

Hydraulic pumps, primary servos, actuators and tail rotor servos have a high failure rate when using the current legacy filters. Dynamic flow testing showed the filters captured and then released a cloud of particles that flowed downstream from the filter into hydraulic components. This condition, known as silting, causes spool valve locking, uncommanded flight control inputs, and increased component wear.

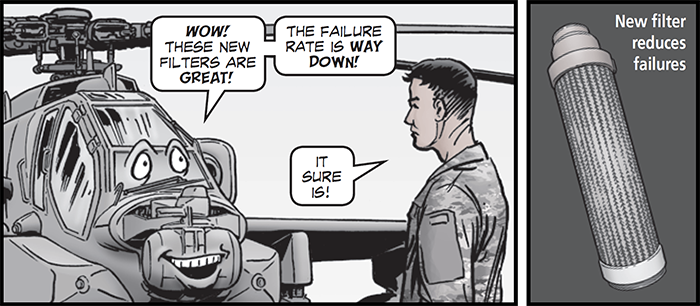

To combat the problem, a series of new, improved filters were tested. Over many flight hours, the new filters removed particulate matter, improved hydraulic fluid cleanliness, and increased the mean time between failures (MTBF) for six key hydraulic components.

For example, the failure rate of the primary hydraulic servos dropped from 310 failures with a MTBF of 648 hours to just 25 failures with a MTBF of 1,389 hours; a 114.3 percent MTBF rate increase. And hydraulic pump replacement went from 285 failures with a MTBF of 705 hours to just 25 with 1,389 MTBF; a 97 percent increase in the MTBF rate.

Hydraulic systems require very clean fluid to make things work. From helicopters to the aviation ground power units (AGPUs) that service aircraft, hydraulic filters are the key to increased operation, reliability and safety.

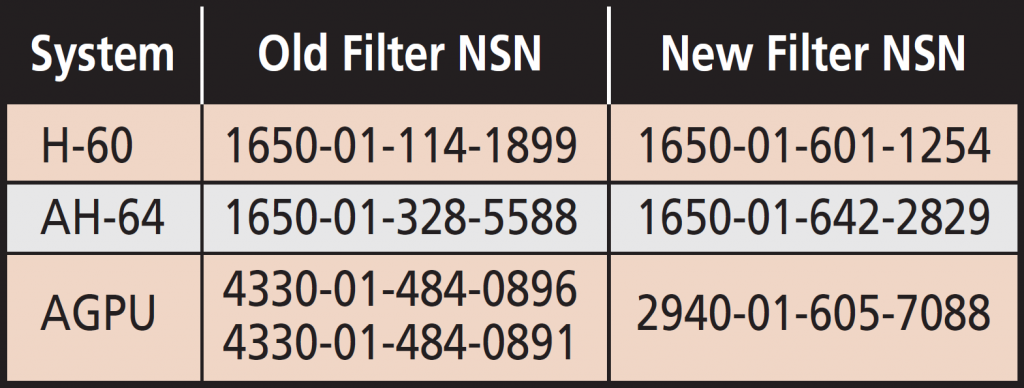

The new filters, which are completely interchangeable with the old ones, will be added to the next TM updates for the H-60, AH-64 and AGPU. Until then, order the new filters from this list:

PTI Technologies 421® Metal Fiber Media: A Solution Proven in Service

A Concept Executed

Human life and equipment are at risk during mission-critical operations if particulate contamination is allowed to weaken aircraft systems. Fortunately, PTI’s 421® Metal Fiber Media filters continue to improve aircraft system performance while maintaining operation schedules, extending the life of expensive system components, improving operational safety and reducing annual maintenance downtime and costs.

Why You Should Make the Change to 421®

- The highest-performing media on the market today

- Improved aircraft system performance, vastly increases life extension of key components, reduces annual maintenance costs

- Superior operational reliability under extreme operating pressures, temperatures, vibration/shock, cyclic flow, and cold start conditions

- Superior filtration performance, lower pressure drop, and a higher contaminant retention capacity than either woven metallic wire cloth or sintered powder metal

- Ideal for filtration of highly-viscous, high-temperature, cryogenic and corrosive fluids

- Completely customizable to meet your design specifications

Learn More

PTI Technologies is a world leader in highly reliable filtration and fluid control equipment and subsystems and miniature CAD/PAD devices. Our product portfolio, used in hydraulics, fuel, thermal management, lubrication, bleed air, environmental air/cabin air, water systems, ejection seats, fire suppression, escape slides, missiles and munitions, is a direct result of our extensive engineering design experience and customer obsession. PTI provides innovative, value-added solutions for a full range of mission, flight and life-critical operations across the Aerospace and Defense markets. PTI Technologies has approximately 250 employees and is part of the Aerospace & Defense Group of ESCO Technologies, a publicly-traded company (NYSE: ESE).

For more information, visit ptitechnologies.com/aerospace/products

Sales Contacts

Brittney San Miguel

PTI

aerospace@ptitechnologies.com

(800) 331-2701

Daniel Zhang

PTI

aerospace@ptitechnologies.com

(800) 331-2701

Latest News

- Using Robust 421® Metal Fiber Media Filtration to Enhance Aircraft System Performance and Reliability

- PTI’s CabinSafe® Products Provide Improved Filtration Technology for the Environmental Control System (ECS) and Bleed Air System

- PTI Technologies Presents at the Army Aviation Association of America